Parameter

Name

Name of the virtual job computer.

External Controller

If you have connected an on-board integrated display/controller or crop protection sensor to the serial interface, you must select the model in this parameter.

The list contains the following devices:

- ▪

- On-board integrated display/controllers that can communicate using one of the protocols ASD or LH5000 and are capable of communicating with the terminal. If you want to connect an on-board integrated display/controller that supports this protocol, but does not appear in the list, please contact Müller-Elektronik and perform the steps shown at the end of this section.

- ▪

- Crop protection sensors that can be connected to the serial interface of the terminal.

- ▪

- AMABUS. Please note that to connect the AMABUS, you need a special cable, item number: 30322572

Procedure

This is how you update the list of on-board integrated display/controllers:

- þ

- You have contacted Müller-Elektronik and received a USB memory device with the installation file.

- þ

- The Virtual ECU application is closed.

- 1.

- Insert the USB memory device into the terminal.

- 2.

- Start the Virtual ECU application.

- ⇨

- The following message appears: Do you want to update the list of external on-board integrated display/controllers?

- 3.

- Select “Yes” to update the list.

- 4.

- Confirm.

- 5.

- Restart the terminal.

- ⇨

- You can now also select the added on-board integrated display/controller.

Implement type

Use this parameter to define the type of implement.

The following implement types are available:

- ▪

- Seeder

- ▪

- Fertilizer spreader

- ▪

- Sprayer

- ▪

- Soil tillage

Connector type

Use this parameter to define the connector type of the agricultural implement.

The following connector types are possible:

- ▪

- Unknown

- ▪

- Drawbar

- ▪

- 3-point hitch mounted

- ▪

- 3-point hitch semi-mounted

- ▪

- Hitch hook

- ▪

- Clevis coupling

- ▪

- Piton-type coupling

- ▪

- CUNA hitch

- ▪

- Ball-type hitch

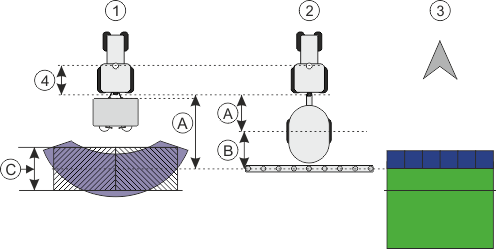

Machine model

This parameter influences how the working bar follows the arrow in TRACK-Leader. The configuration improves the precision of the recording of applied areas in curves.

After each change, you also need to adjust the geometry.

Possible values:

- ▪

- “mounted”

- Setting for implements that are mounted on the tractor three-point hitch.

- ▪

- “trailed”

- Settings for implements trailed by a tractor. The working bar is guided like a trailer behind a tractor.

Working width

This parameter shows the working width set for an implement.

Number of sections

Enter the number of sections that can be switched off on the implement. On a field sprayer, they are the section valves; on a fertilizer spreader or a planter/seeder, they can be e.g. metering units.

This parameter serves to transmit the proper number of sections to the SECTION-View module, so that you can switch the sections manually.

Each section appears as part of the working bar on the screen.

Sections

Opens a screen where you can enter the width of the individual sections on the implement.

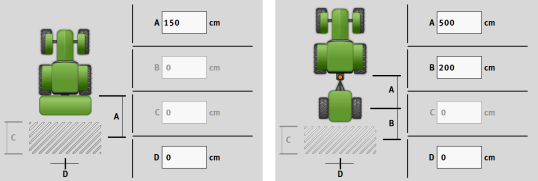

Geometry

The geometry contains a series of dimensions that help to properly display the vehicle-implement combination in TRACK-Leader and determine its position.

To call up the geometry, tap the function icon:

TRAMLINE-View

TRAMLINE-View contains parameters that are used to correctly display tramlines in TRACK-Leader when using seeders.

To use TRAMLINE-View, the “TRAMLINE-Management” license must be activated.

To call up TRAMLINE-View, tap the function icon:

Parameter:

- ▪

- “Tramline rhythm”

- Defines the tramline rhythm to be used for operation.

- ▪

- “Working Start”

- Defines the point on the field at which you want to start working.

- ▪

- “Begin with half the working width”

- Defines whether you make the first field track after starting to work with only half of the working width.